Car production tumbles afresh amid supply and labour shortages

Car production tumbled in the UK for the first time since February as the combination of global chip shortages, workers being forced to isolate, and summer shutdowns jammed up factory lines.

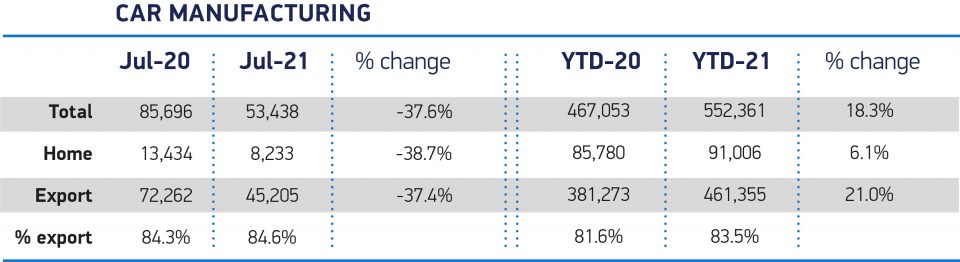

According to the Society of Motor Manufacturers and Traders (SMMT), just 53,438 cars were made in July, down 37.6 per cent on the year before.

It is the worst July for auto output since 1956, when 51,472 cars were produced.

Over a quarter – 26.0 per cent – of all cars made last month were either battery electric (BEV), plug in hybrid (PHEV) or hybrid electric (HEV), their highest share on record.

Despite the lifting of Covid-19 restrictions earlier this summer, the car industry has been plagued by a number of supply and labour issues that have hammered production.

All year car firms have been warning that the shortage of semiconductors would force them to cut production and idle workers.

Recently, Toyota said that it would slash production 40 per cent in September, with Volkswagen also warning of further cuts.

Jim Holder, editorial director, What Car?, said that it was unlikely that production issues would be resolved until 2022.

“Until then, manufacturers have to manage customer demand and expectations”, he said.

But Richard Peberdy, head of auto at KPMG, warned that the supply problems could begin to affect prices.

“Manufacturers are absorbing the costs for now, but we could soon see price rises being passed on to consumers should problems persist, which runs the risk of dampening the sales recovery.”

In addition, thousands of factory staff have been forced to isolate after being alerted by the Covid-19 app amid the so-called “pingdemic”.

Although isolation rules have since been eased for fully-vaccinated people, labour shortages have continued to weigh on carmakers.

Mike Hawes, SMMT chief executive, said, “These figures lay bare the extremely tough conditions UK car manufacturers continue to face. While the impact of the ‘pingdemic’ will lessen as self-isolation rules change, the worldwide shortage of semiconductors shows little sign of abating.

“The UK automotive industry is doing what it can to keep production lines going, testament to the adaptability of its workforce and manufacturing processes, but government can help by continuing the supportive Covid measures currently in place and boosting our competitiveness with a reduction in energy levies and business rates for a sector that is strategically important in delivering net zero.”

For the year to date, production is up 18.3 per cent on 2020, when factories were shut for a number of months due to the pandemic.

However, the 552,361 units made so far is 28.7 per cent down on 2019 levels.